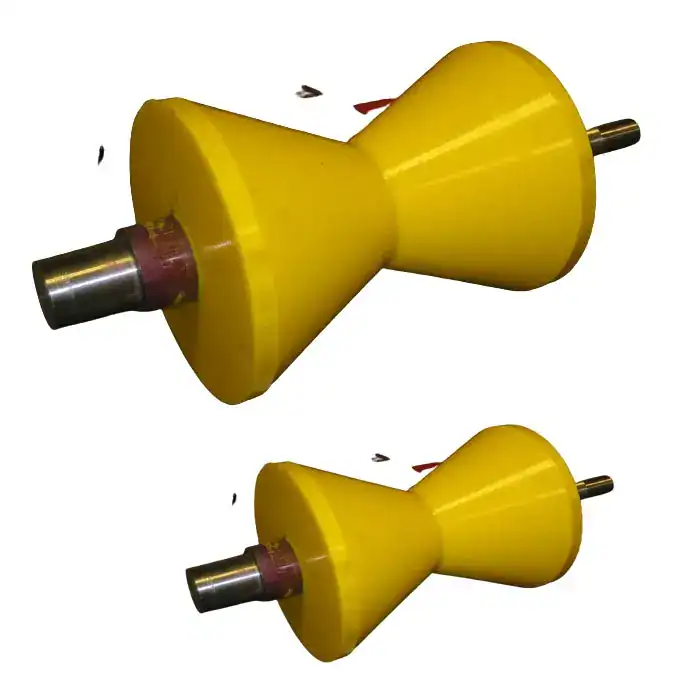

Western Polymers’ polyurethane elastomers are ideal for coating wheels and rollers. Whether it’s an existing roller that needs to be reconditioned or a core that is being coated for the first time, Western Polymers has several proven materials for use in any application.

Replacing deteriorated tread material with high-performance polyurethane or rubber helps manufacturers extend asset life, reduce downtime, and avoid the high cost of full wheel replacement.

Our reconditioning process is ideal for wheels used in demanding applications such as material handling, agriculture, manufacturing equipment, conveyors, and specialized industrial systems.

Our tooling ensures that production runs will provide dimensionally consistent high quality finished goods.

Since 1994, Western Polymers has supported industrial customers with dependable elastomer solutions designed for real-world performance.

Have worn wheels that may be suitable for reconditioning?

Contact Western Polymers to receive a cost-effective reconditioning solution.